An Introduction to NEC-Compliant Torque Labels

In the intricate world of electrical installations, attention to detail is paramount. Importantly, a key aspect involves ensuring technicians tighten all connections to the manufacturer’s specified torque, as the National Electrical Code (NEC) 110.14(D) mandates. Moreover, compliance is not just about adhering to regulations; it’s fundamentally about safeguarding lives and properties. Consequently, torque labels play a pivotal role in this process, providing visible proof of adherence to safety standards and meticulous care in electrical installations.

The Significance of NEC 110.14(D)

NEC 110.14(D) represents more than a guideline; it’s a vital safety requirement ensuring the integrity of every electrical connection. Incorrect torque can lead to loose or overly tight connections, both of which pose significant risks such as arcing, overheating, and potential fires. Compliance with this code reflects an electrician’s dedication to quality and safety, qualities that are essential for long-lasting and safe electrical installations.

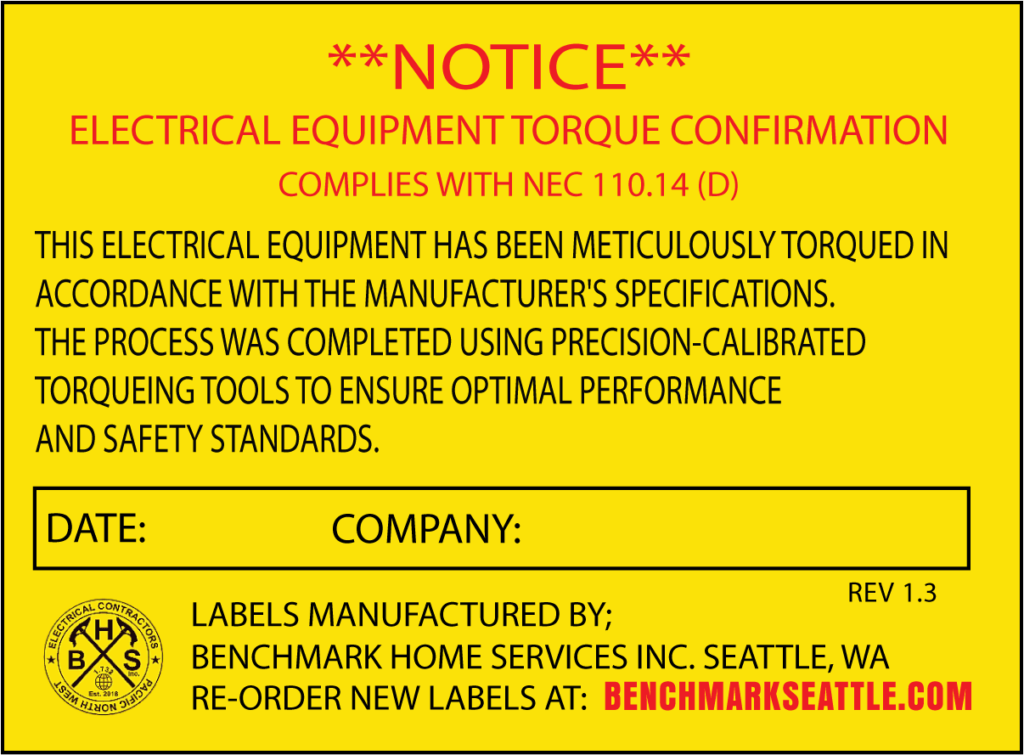

Introducing Torque Labels: Your Compliance Ally

NEC-compliant torque labels are crucial yet often overlooked tools in electrical safety. Firstly, these adhesive indicators validate that an installation adheres to precision and care standards. Furthermore, they act as the electrician’s badge of professionalism. Finally, they provide the client with assurance that the installation meets rigorous safety standards.

Why NEC-Compliant Torque Labels Matter

Ignoring torque specifications can have dire consequences, ranging from equipment malfunction to severe safety hazards. Torque labels constantly remind and physically record that proper procedures have been followed. They are an indispensable part of any comprehensive electrical safety protocol.

Expanding on the Importance of Torque Labels

NEC-compliant torque labels are not just about compliance; they are about promoting a culture of safety in electrical work. They remind technicians and inspectors of the critical importance of torque settings, thereby reducing the likelihood of oversight or error. These labels also serve an educational purpose, reinforcing best practices among electricians and raising awareness about the critical nature of correct torque application.

The Evolution of NEC-compliant torque labels

Over the years, torque labels have evolved in design and functionality. Modern torque labels may include QR codes that link to detailed installation instructions or videos, providing additional guidance to technicians. This technological integration enhances the utility of torque labels, making them more than just compliance tools but also resources for best practice adherence.

Implementing Torque Label Programs

To maximize the benefits of torque labels, firstly, electrical contracting firms should implement comprehensive torque label programs. These programs should include training on the importance of torque settings, proper label application, and methods for verifying compliance. Additionally, regular audits and inspections can ensure ongoing adherence to NEC 110.14(D) and the effective use of torque labels.

Why it Matters

The critical role of NEC-compliant torque labels in electrical safety cannot be overstated. They are more than mere regulatory requirements; they represent a commitment to excellence and safety in electrical installations. By adopting and rigorously implementing torque label programs, the electrical industry can significantly enhance safety standards, protect properties, and save lives.

Additional Resources:

- National Fire Protection Association (NFPA): For comprehensive information on NEC standards and electrical safety.

- Electrical Safety Foundation International (ESFI): A non-profit organization dedicated to promoting electrical safety in the home and workplace.

- Occupational Safety and Health Administration (OSHA) Electrical Safety Guidelines: Offers guidelines and resources for electrical safety in the workplace.